Equipment complex for

inspection of

oil & gas complex.

OUTLINE

This article provides information on the composition and capabilities of the hardware and software complex for inspection of subsea facilities of oil and gas complex, developed and expanded for solving an increasingly wide range of tasks in the For Systems company. Different variants of the complex allow to survey and monitor the condition of various objects - from underwater pipeline crossings to production platforms and their infrastructure on the shelf and hydraulic structures of onshore terminals. Based on the results of work performed using the complex, reporting materials are generated, including digital models of relief and underwater part of objects, drawings, profiles, sections, three-dimensional models. All these materials can be easily integrated into GIS systems and databases.

This article provides information on the composition and capabilities of the hardware and software complex for inspection of subsea facilities of oil and gas complex, developed and expanded for solving an increasingly wide range of tasks in the For Systems company. Different variants of the complex allow to survey and monitor the condition of various objects - from underwater pipeline crossings to production platforms and their infrastructure on the shelf and hydraulic structures of onshore terminals. Based on the results of work performed using the complex, reporting materials are generated, including digital models of relief and underwater part of objects, drawings, profiles, sections, three-dimensional models. All these materials can be easily integrated into GIS systems and databases.

Introduction

All subsea facilities of oil and gas complex are potentially hazardous and require periodic routine inspections and careful technical supervision and control during construction. Such facilities include underwater pipeline crossings, underwater parts of production platforms installed on the shelf, process pipelines connecting production platforms and onshore infrastructure facilities, trunk pipelines laid on the seabed, underwater structures of onshore infrastructure facilities, oil and gas terminals. At present, various variants of equipment and software complexes are used to control the technical condition of these objects. The most convenient complexes are those that ensure the fulfilment of the whole list of works in a single cycle from surveying works to the formation of reporting materials. Until recently it was necessary to use the most complex components of complexes, such as multibeam echo sounders (MBE), sound or scanning MBE, teleoperated unmanned underwater vehicles (UUV), underwater navigation systems, software.

In recent years, considerable effort has been expended by our leading equipment developers to develop subsea performance tools that will cover most of the subsea monitoring needs. The intermediate result of this ongoing work is multifunctional complexes that provide solutions for almost all tasks arising in the survey of underwater objects.

Methods

The composition of the complex for solving each type of tasks depends on the type of surveyed objects. The most widespread and demanded complexes are Automated mobile complexes for survey of water areas and pipelines with ship electromagnetic tracer. The most complete composition of these complexes includes the following set of equipment and software:

- ForBathy hydrographic echo sounder

- GNSS equipment set FlyBox

- Side scan sonar ForScan

- Ship's tracefinder system with tracefinder ForPipe

- Hydrological equipment (flow velocity meter with flow direction determination module, surface layer flow velocity meter)

- Software for surveying

- Software for data processing and report generation

- Software for data presentation.

These complexes are used for scheduled periodic surveys of underwater crossings of pipelines and communication cables, technical supervision during construction and repair of underwater crossings and underwater technical works.

Hydrographic echo sounders included in these complexes provide centimetre depth resolution and operate at depths of up to 200 metres. GNSS equipment sets realise operation in RTK-mode (Real Time Kinematic) with centimetre accuracy in kinematics when receiving differential corrections from a base station installed by users or from a stationary base station. The ship's trace locator allows to determine the plano-altitude position of underwater pipelines and cables at depths up to 30 metres. Side-scan sonar generates high-resolution hydroacoustic image of the bottom surface with objects on it, allows to determine coordinates, shape and size of objects, bottom structure, to place marks of found objects on the navigation map in real time mode. Hydrological equipment with specialised modules allows to perform hydrological measurements of flow velocity at horizons. The survey software ensures co-operation of all the equipment, planning of the survey process according to the required scale, helps the ship operator to conduct the survey on the required transects and provides all the necessary ship navigation and navigation functions. Data processing software on the basis of the data recorded during the survey performs processing, evaluates convergence and accuracy of the data obtained, performs "tack comparison" to control the survey quality, takes into account water level changes during the survey. As a result of processing, complete sets of reporting materials are formed in accordance with the requirements of industry regulations. Examples of final information obtained with this configuration of the complex are shown in Pictures 1 and 2.

All subsea facilities of oil and gas complex are potentially hazardous and require periodic routine inspections and careful technical supervision and control during construction. Such facilities include underwater pipeline crossings, underwater parts of production platforms installed on the shelf, process pipelines connecting production platforms and onshore infrastructure facilities, trunk pipelines laid on the seabed, underwater structures of onshore infrastructure facilities, oil and gas terminals. At present, various variants of equipment and software complexes are used to control the technical condition of these objects. The most convenient complexes are those that ensure the fulfilment of the whole list of works in a single cycle from surveying works to the formation of reporting materials. Until recently it was necessary to use the most complex components of complexes, such as multibeam echo sounders (MBE), sound or scanning MBE, teleoperated unmanned underwater vehicles (UUV), underwater navigation systems, software.

In recent years, considerable effort has been expended by our leading equipment developers to develop subsea performance tools that will cover most of the subsea monitoring needs. The intermediate result of this ongoing work is multifunctional complexes that provide solutions for almost all tasks arising in the survey of underwater objects.

Methods

The composition of the complex for solving each type of tasks depends on the type of surveyed objects. The most widespread and demanded complexes are Automated mobile complexes for survey of water areas and pipelines with ship electromagnetic tracer. The most complete composition of these complexes includes the following set of equipment and software:

- ForBathy hydrographic echo sounder

- GNSS equipment set FlyBox

- Side scan sonar ForScan

- Ship's tracefinder system with tracefinder ForPipe

- Hydrological equipment (flow velocity meter with flow direction determination module, surface layer flow velocity meter)

- Software for surveying

- Software for data processing and report generation

- Software for data presentation.

These complexes are used for scheduled periodic surveys of underwater crossings of pipelines and communication cables, technical supervision during construction and repair of underwater crossings and underwater technical works.

Hydrographic echo sounders included in these complexes provide centimetre depth resolution and operate at depths of up to 200 metres. GNSS equipment sets realise operation in RTK-mode (Real Time Kinematic) with centimetre accuracy in kinematics when receiving differential corrections from a base station installed by users or from a stationary base station. The ship's trace locator allows to determine the plano-altitude position of underwater pipelines and cables at depths up to 30 metres. Side-scan sonar generates high-resolution hydroacoustic image of the bottom surface with objects on it, allows to determine coordinates, shape and size of objects, bottom structure, to place marks of found objects on the navigation map in real time mode. Hydrological equipment with specialised modules allows to perform hydrological measurements of flow velocity at horizons. The survey software ensures co-operation of all the equipment, planning of the survey process according to the required scale, helps the ship operator to conduct the survey on the required transects and provides all the necessary ship navigation and navigation functions. Data processing software on the basis of the data recorded during the survey performs processing, evaluates convergence and accuracy of the data obtained, performs "tack comparison" to control the survey quality, takes into account water level changes during the survey. As a result of processing, complete sets of reporting materials are formed in accordance with the requirements of industry regulations. Examples of final information obtained with this configuration of the complex are shown in Pictures 1 and 2.

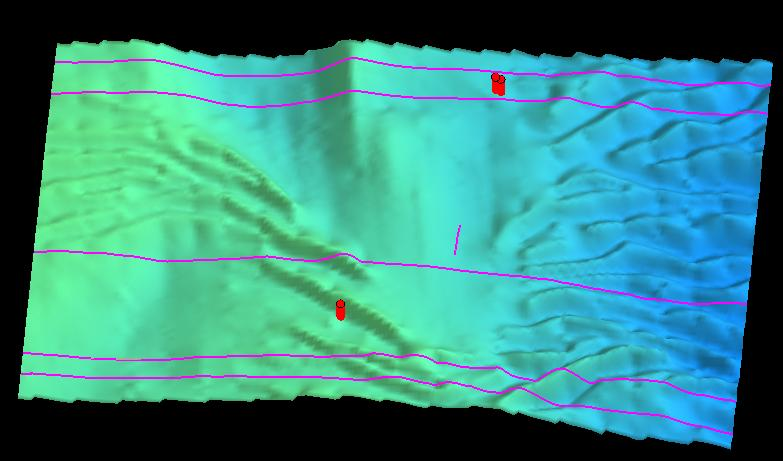

Pic.1. Bathymetric section of the underwater crossing

Pic.2. Three-dimensional model of the underwater crossing section

Multibeam echo sounders are used for more complex tasks associated with high-resolution hydrographic surveying.

To solve this task, For Systems developed multi-sonar software that provides operation with various models of MLEs, side-scan sonars, GNSS equipment, inertial systems, sound velocity sensors and other equipment necessary to perform these works. The Acoustic Institute developed a multibeam echo sounder with the necessary characteristics for hydrographic surveys. ForSystems developed and manufactured the sound velocity sensor and sound velocity profiler necessary to support MLE operations. The use of a three-frequency SSS with a wide swath made it possible to perform high-resolution hydroacoustic profiling of the seabed surface simultaneously with the hydrographic survey and to integrate the data into a digital model of the seabed relief. Together with our partners, integrated solutions of GNSS equipment and inertial systems were created to enable the MLE survey in conditions of temporary loss of satellite signals, e.g. under bridges, close to HS walls, etc. The result of this work was a full-featured complex for high-resolution hydrographic survey and inspection of the underwater part of hydraulic structures in the following composition:

- Multibeam echo sounder

- Sound speed sensor

- Sound velocity profiler

- GNSS equipment integrated with inertial system

- Shipboard side scan sonar

- Single beam hydrographic echo sounder

- Specialised multi-person data acquisition software

- Specialised data processing software

Such a complex in the configuration of the trawl complex and the configuration of the hydrographic complex has undergone pilot operation in the navigation of 2019-2020 and continues to be developed and upgraded to the fullest compliance with the requirements of users and the formation of final materials in accordance with the requirements of regulatory documents and in the most convenient and visual form, not inferior to analogues. A fragment of the working screen of the multisonar programme at the operation of the MLE and SSS during the pilot operation is shown in in Picture 3.

The section of the harbour wall obtained using the complex with multibeam echosounder is shown in Picture 4.

To solve this task, For Systems developed multi-sonar software that provides operation with various models of MLEs, side-scan sonars, GNSS equipment, inertial systems, sound velocity sensors and other equipment necessary to perform these works. The Acoustic Institute developed a multibeam echo sounder with the necessary characteristics for hydrographic surveys. ForSystems developed and manufactured the sound velocity sensor and sound velocity profiler necessary to support MLE operations. The use of a three-frequency SSS with a wide swath made it possible to perform high-resolution hydroacoustic profiling of the seabed surface simultaneously with the hydrographic survey and to integrate the data into a digital model of the seabed relief. Together with our partners, integrated solutions of GNSS equipment and inertial systems were created to enable the MLE survey in conditions of temporary loss of satellite signals, e.g. under bridges, close to HS walls, etc. The result of this work was a full-featured complex for high-resolution hydrographic survey and inspection of the underwater part of hydraulic structures in the following composition:

- Multibeam echo sounder

- Sound speed sensor

- Sound velocity profiler

- GNSS equipment integrated with inertial system

- Shipboard side scan sonar

- Single beam hydrographic echo sounder

- Specialised multi-person data acquisition software

- Specialised data processing software

Such a complex in the configuration of the trawl complex and the configuration of the hydrographic complex has undergone pilot operation in the navigation of 2019-2020 and continues to be developed and upgraded to the fullest compliance with the requirements of users and the formation of final materials in accordance with the requirements of regulatory documents and in the most convenient and visual form, not inferior to analogues. A fragment of the working screen of the multisonar programme at the operation of the MLE and SSS during the pilot operation is shown in in Picture 3.

The section of the harbour wall obtained using the complex with multibeam echosounder is shown in Picture 4.

To perform visual inspection of underwater pipelines and offshore production platforms and their infrastructure, a complex based on a family of underwater teleoperated vehicles was formed. The modular configuration of the vehicle, as modified for For Systems, allows the vehicle to accommodate not only the traditional for TNPAs circular sonar, but also various models of underwater navigation system sensors and high-resolution hydroacoustic means to obtain a detailed picture of the elements of hydraulic structures. The TNPA can operate at depths of up to 300 metres with a cable length of up to 600 metres, it is equipped with four underway vector thrusters and two vertical thrusters, two high-resolution video cameras, a manipulator, a laser distance meter, and an all-round sonar. As "payloads" it is fitted with a 2D or 3D sonar, underwater navigation system. The For Systems software allows the operator to see in real time the position of the TNPA on a 3D model of the water area and control its movement.

Results and discussions

Thus, hardware-software complexes have been formed and put into operation to solve the main range of tasks related to inspection and monitoring of subsea objects of oil and gas complex on the basis of fully proprietary solutions. These solutions in the simplest configuration for inspection of underwater crossings on inland water bodies are widely implemented and operated by users. Thus our users use more than 70 sets of equipment and software as part of such complexes. Constant contact with users allows to receive feedback and necessary information to ensure further development of these tools. In particular, references to the elements of the complex, used as part of various systems, are found in the description of works performed on complex objects.

More complex configurations of the complex with MLE are currently being put into operation and should become a worthy alternative, provided with qualified commissioning, user training, technical support and metrological support.

Results and discussions

Thus, hardware-software complexes have been formed and put into operation to solve the main range of tasks related to inspection and monitoring of subsea objects of oil and gas complex on the basis of fully proprietary solutions. These solutions in the simplest configuration for inspection of underwater crossings on inland water bodies are widely implemented and operated by users. Thus our users use more than 70 sets of equipment and software as part of such complexes. Constant contact with users allows to receive feedback and necessary information to ensure further development of these tools. In particular, references to the elements of the complex, used as part of various systems, are found in the description of works performed on complex objects.

More complex configurations of the complex with MLE are currently being put into operation and should become a worthy alternative, provided with qualified commissioning, user training, technical support and metrological support.